Electrical systems rely on stable, consistent, and reliable power flow, yet this performance depends heavily on the insulation and protection of busbars. Modern facilities now recognize busbar powder coating as a long-term solution that strengthens safety, efficiency, and overall electrical reliability. As electrical infrastructure grows more complex, demand continues to rise for coating technologies engineered for durability, temperature resistance, and precise coverage across varied geometric profiles.

Industrial operations in manufacturing, renewable energy, utilities, and data centers require consistent insulation that withstands harsh conditions. With increasing emphasis on advanced busbar epoxy coating, busbar insulation coating, and specialized busbar coating systems, organizations seek coating methods that extend asset lifespan while minimizing maintenance interruptions.

1. Superior Electrical Insulation and Dielectric Strength

Busbars carry high electrical loads, making insulation performance a critical safety factor. Busbar powder coating creates a uniform, electrically insulating layer that helps prevent arc-flash hazards, short circuits, and conductive bridging.

Key advantages include:

- High dielectric strength suitable for both high- and low-voltage systems

- Consistent electrical insulation across edges, corners, and complex profiles

- Strong protection against partial discharge and electrical leakage

- Stable performance in environments with fluctuating voltage loads

Compared to conventional dipping or brushing methods, powder coatings ensure much more controlled and consistent film build, resulting in reliable dielectric properties that support continuous electrical operation.

2. Enhanced Corrosion and Oxidation Resistance

Metal busbars, especially copper and aluminum, are susceptible to corrosion, oxidation, and chemical exposure over time. Even minor surface oxidation increases electrical resistance and reduces system efficiency.

Busbar epoxy coating and powder-based insulation coatings offer strong resistance to:

- Humidity and moisture

- Chemical vapors

- Industrial contaminants

- Environmental oxidation

By creating a sealed, protective barrier, busbar coatings significantly slow down degradation. This extends the operational lifespan of electrical equipment and reduces the risk of unexpected failures, particularly in industrial and outdoor environments.

3. Improved Thermal Stability Under Load

Electrical systems generate heat during operation, and unmanaged thermal buildup leads to insulation breakdown, inefficiency, and potential safety hazards. Busbar powder coating enhances thermal stability by maintaining structural integrity under elevated temperatures.

Thermal-resistant properties include:

- Minimal softening or deformation during prolonged heat exposure

- Stable dielectric performance despite rapid load fluctuations

- Reduced risk of thermal fatigue and cracking

- Better overall temperature distribution across coated surfaces

This makes powder-coated busbars particularly valuable in applications such as switchgear, renewable energy grids, power distribution units, and high-load electrical panels. For environments where electrical continuity is critical, thermal resilience is indispensable.

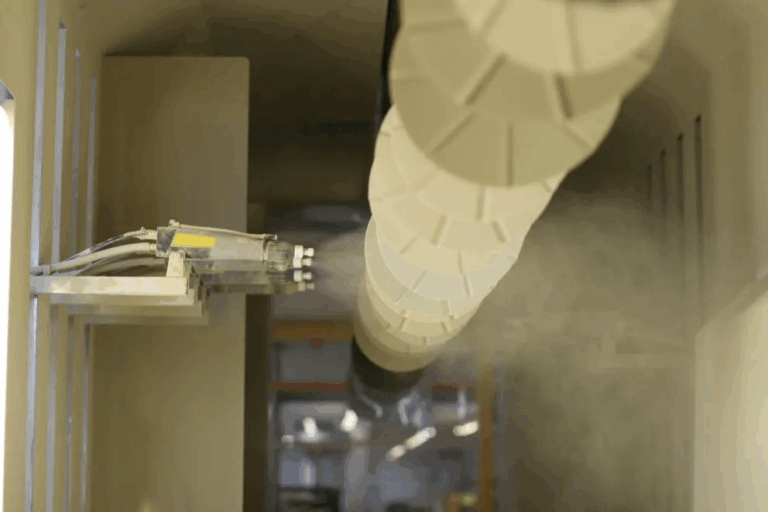

4. Uniform Thickness and Mechanical Durability

One of the strongest advantages of busbar powder coating is its ability to produce a uniform coating thickness—something difficult to achieve using dipping or spray-on liquid insulation. Uneven thickness creates weak points that compromise insulation, reduce dielectric strength, and introduce mechanical vulnerabilities.

Powder coating technology ensures:

- Consistent film thickness across the entire busbar

- Smooth edge coverage without runs or drips

- Strong adhesion that resists chipping, cracking, and abrasion

- Enhanced mechanical resistance to vibration and physical contact

This uniformity supports long-term electrical stability and lowers maintenance requirements, especially in systems with frequent operational cycles.

5. Compliance with NEMA and IEC Standards

Electrical infrastructure must meet strict safety and performance regulations. Powder-coated busbars align with standards set by:

- NEMA (National Electrical Manufacturers Association)

- IEC (International Electrotechnical Commission)

- ASTM performance and mechanical durability standards

Compliance ensures that insulated busbars:

- Meet dielectric strength requirements

- Maintain consistent insulation thickness

- Withstand environmental and mechanical stress

- Perform reliably within defined voltage classifications

Busbars coated through certified Busbar epoxy coating services achieve better traceability and quality control, helping industrial facilities meet regulatory and safety expectations without compromise.

6. Eco-Friendly and Cost-Efficient Protection

Powder coatings offer significant sustainability advantages over traditional liquid coatings. The process contains no solvents, reduces hazardous waste, and minimizes overspray losses through reclaim systems. This aligns with modern industry goals focused on environmental responsibility.

Cost advantages include:

- Lower long-term maintenance

- Reduced coating failures

- Extended equipment lifespan

- Minimized rework due to consistent coating uniformity

Busbar epoxy coating for electrical insulation delivers a strong barrier without requiring frequent replacement or repair. The long-term savings make it a cost-effective choice for large-scale electrical installations and high-demand distribution systems.

Smarter Coating, Safer Power Distribution

Electrical infrastructure depends on coatings that deliver stability, safety, and durability. Busbar powder coating strengthens dielectric performance, reduces corrosion-related failures, enhances mechanical durability, and ensures compliance with global electrical standards. When combined with high-performance epoxy coatings, it offers a comprehensive insulation system built for the demands of modern power networks.

Professional Powder Coating provides reliable, precision-applied busbar coatings engineered for long-term electrical safety and system performance. Connect with us today to ensure every busbar is protected with industry-grade insulation designed for high-demand environments.