When it comes to building in the United States, the foundations matter. Every structure, big or small, begins with careful planning. Strong design ensures safety, efficiency, and long-term durability. That’s why today’s construction projects rely heavily on advanced tools and precise workflows.

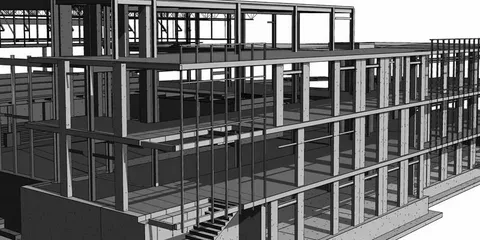

Modern construction teams increasingly turn to bim structural modeling services to simplify their processes. These services allow engineers, architects, and contractors to collaborate in real-time. Teams can detect conflicts early and avoid costly delays. They also streamline communication across multiple disciplines. When everyone sees the same accurate model, errors drop and confidence rises.

Structural planning involves more than drawings. It’s about understanding how each material, joint, and system works together. Engineers need to visualize loads, stresses, and connections. Digital models make this easier. Teams can test scenarios before any physical work begins. The benefits go beyond cost savings; they improve safety and quality.

Another advantage of BIM in structural modeling is efficiency. Instead of waiting for multiple rounds of revisions, teams can update models instantly. Changes propagate across all plans. That means the construction crew always works with the latest information. It also reduces disputes between contractors and owners. For projects across the United States, this level of control is invaluable.

When combined with traditional expertise, bim structural modeling services deliver powerful results. Experienced engineers can interpret the models, make informed decisions, and foresee challenges. Whether constructing a residential building or a complex commercial facility, these services improve workflow, reduce waste, and ensure structural integrity.

Understanding Construction Materials

Choosing the right materials is another crucial aspect of structural planning. Material selection affects durability, cost, and performance. Concrete, steel, wood, and masonry all play roles depending on the project type. Each material has advantages and limitations. Understanding these nuances allows teams to design smarter, safer structures.

For example, concrete is strong under compression but weak in tension. Reinforced concrete, paired with steel rebar, provides balanced strength. Wood is lightweight and versatile, but it may need treatment against moisture or pests. Steel beams offer excellent load-bearing capacity but can be costly. Balancing these factors is key in structural planning.

Masonry is another common choice. Builders often use concrete masonry units (CMUs) for walls and partitions. Knowing standard cmu block sizes helps streamline construction and reduces material waste. Teams can plan layouts more efficiently, calculate costs accurately, and ensure walls fit structural requirements. For projects across the United States, adhering to standard sizes improves consistency and speeds up approvals.

Standard block sizes also impact insulation, finishing, and joint placement. Engineers can coordinate electrical and plumbing layouts around predictable dimensions. Contractors can plan work sequences effectively. Overall, familiarity with material standards saves time and prevents errors during construction.

Practical Tips for Effective Structural Planning

Planning a structure requires foresight and attention to detail. Here are some practical tips to strengthen any project:

1. Start with Accurate Data

Collect precise site measurements and soil reports. Digital models work best with correct input data.

2. Choose the Right Materials

Consider load requirements, climate, and longevity. Match materials to the design and budget.

3. Use Digital Modeling Tools

Tools like BIM allow real-time collaboration and clash detection. It keeps teams aligned and informed.

4. Coordinate Across Disciplines

Mechanical, electrical, and structural teams must work together. Frequent reviews prevent conflicts.

5. Plan for Flexibility

Construction projects often change. Models should accommodate design adjustments without major delays.

6. Track Costs and Schedules

Integrate material costs and timelines in your planning. Accurate tracking avoids overruns.

7. Consult Experts When Needed

Experienced engineers or consultants can provide insights on materials and workflows, especially on complex projects.

8. Document Everything

Maintain records of decisions, material selections, and model updates. Documentation reduces misunderstandings.

By applying these tips, teams can ensure smooth, efficient, and safe project execution.

Choosing the Right Tools

Digital tools are now central to structural planning. Software solutions allow teams to create detailed models, analyze loads, and simulate performance. Many platforms also support collaboration across multiple locations. This is particularly useful for teams in the United States who work on large or remote sites.

Some tools provide automated checks for material quantities and structural compliance. Others help visualize designs in 3D or even virtual reality. Selecting the right combination depends on project size, complexity, and budget.

Using expert services ensures the tools are applied effectively. Engineers can interpret complex outputs and make decisions quickly. Teams that rely solely on software without guidance may miss critical issues. That’s why pairing bim structural modeling services with skilled professionals delivers the best outcomes.

Integrating Material Knowledge

Understanding materials is equally important as modeling them. Different materials behave differently under stress, heat, or moisture. Combining BIM models with material expertise allows teams to plan effectively.

For masonry walls, knowing standard cmu block sizes streamlines structural planning. Builders can anticipate joint placement, reinforcement requirements, and finishing details. Proper coordination between the model and the material ensures smoother construction and fewer mistakes.

Steel, concrete, and wood each have unique properties. Models can simulate their behavior under real-world conditions. Teams can adjust designs before construction begins, saving both time and money. By integrating modeling and material knowledge, construction becomes more predictable and reliable.

Sustainability Considerations

Sustainable construction is increasingly important in the United States. Choosing environmentally friendly materials and efficient construction practices can reduce waste and energy consumption. BIM modeling allows teams to test energy performance, optimize materials, and plan recycling or reuse of resources.

For example, predicting concrete volumes accurately reduces overordering. Using recycled steel or timber can lower the project’s carbon footprint. Even small adjustments in material selection can have long-term environmental benefits. Combining sustainability with digital modeling supports modern construction goals.

Collaboration and Communication

One of the biggest challenges in construction is communication. Misunderstandings between architects, engineers, and contractors lead to delays and extra costs. Digital modeling tools act as a central platform for collaboration. Every stakeholder sees the same accurate data, minimizing mistakes.

Teams can schedule regular model reviews to identify clashes or inconsistencies. This proactive approach ensures that construction proceeds smoothly. It also builds trust among stakeholders. Projects that prioritize communication often finish faster and stay within budget.

Long-Term Benefits

The advantages of combining structural planning with BIM services are not limited to construction. Accurate models support future renovations, maintenance, and expansions. Owners can access digital records to understand building layouts, materials used, and system placements.

Predictable construction leads to higher-quality buildings. Reduced errors mean fewer repairs, better energy efficiency, and lower long-term costs. Investing in proper planning pays off for decades.

For residential, commercial, or industrial projects across the United States, structured planning and material knowledge improve safety, durability, and overall project success.

Practical Example: Masonry Walls

Let’s take an example. A contractor building a commercial facility in the U.S. plans to use CMU walls. By applying standard cmu block sizes, they can:

- Optimize wall layouts

- Reduce material waste

- Ensure uniformity for finishes and insulation

- Plan reinforcement placement accurately

When combined with a BIM model, these considerations are visualized and verified before construction starts. This avoids on-site surprises and keeps the project on schedule.

Final Thoughts

Structural planning and material selection are the backbone of successful construction. Digital tools, expert guidance, and knowledge of materials allow teams to deliver high-quality, durable structures. In the United States, these practices ensure safety, efficiency, and long-term value.

Using bim structural modeling services paired with a clear understanding of standard cmu block sizes allows teams to anticipate challenges, optimize resources, and build smarter. Whether the project is residential, commercial, or industrial, combining expertise, materials knowledge, and digital modeling is a winning approach.

FAQ

1. What are BIM structural modeling services?

BIM structural modeling services create digital representations of structures to improve accuracy, detect clashes, and enhance collaboration.

2. Why are standard CMU block sizes important?

They help plan wall layouts efficiently, reduce material waste, and simplify reinforcement placement.

3. Can small construction projects benefit from these services?

Yes. Even small renovations can gain better planning, fewer errors, and smoother execution with BIM services.

4. How do these tools save costs?

By detecting conflicts early, optimizing materials, and reducing rework on-site.

5. Are these practices used widely in the United States?

Yes. Many U.S. construction projects, both commercial and residential, rely on BIM and material standards.