component replacements, or material transitions. One crucial question is which polyethylene variant delivers reliable performance. This decision becomes even more important when operations involve heavy loads, corrosive environments, or long-term outdoor exposure. Selecting the wrong grade can lead to premature wear, unexpected downtime, and costly maintenance.

Polyethylene materials offer versatility, durability, and long service life. Yet each grade, high-density polyethylene (HDPE) and low-density polyethylene (LDPE), behaves differently under pressure, impact, heat, and chemical exposure. Understanding these differences is essential for choosing the best material for demanding industrial applications.

Understanding Polyethylene and Its Industrial Advantages

Polyethylene is one of the most common thermoplastics in industrial operations. It offers:

- Strong resistance to corrosion

- Excellent durability against moisture

- Low-friction characteristics

- Stable performance in rugged conditions

Both HDPE and LDPE fall within the same family. However, structural differences in their molecular arrangements yield unique benefits for specific industrial environments.

What Makes High-Density Polyethylene Distinct?

High-density polyethylene contains tightly packed molecular chains. This structure provides the material with greater rigidity and increased resistance to external forces. Common industrial benefits include:

- Strong tensile performance

- Excellent chemical resistance

- Low moisture absorption

- High impact strength

- Stability in outdoor and harsh conditions

This material is also one of the most stable and cost-effective options for long-term use. It is a preferable choice when high strength and rigidity are vital.

Where High-Density Polyethylene Delivers Strong Performance

Many operations rely on HDPE when heavy use and environmental stress are key considerations. Typical applications include:

- Wear strips and guides in material handling

- Chutes, hoppers, and liners for mining and bulk processing

- Water and chemical tanks

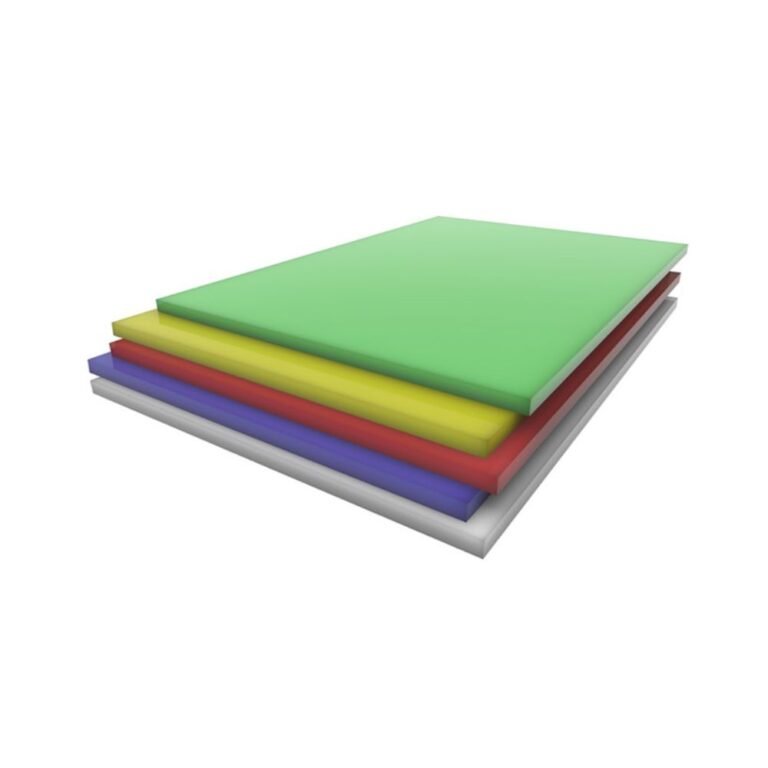

- Industrial cutting boards and work surfaces

- Pipe systems for fluid transfer

- Components for agricultural and construction equipment

HDPE sheets and rods provide consistent behaviour in applications that experience repeated load, abrasion, or outdoor exposure.

What Defines Low-Density Polyethylene?

Low-density polyethylene has a different molecular structure with more spacing between chains. This creates a softer, more flexible material. LDPE offers:

- High flexibility even in cold temperatures

- Strong impact resistance

- Easy forming and processing

- Good chemical resistance

- Smooth surface finish

While LDPE is not as rigid as HDPE, its flexibility makes it suitable for applications that require bending, shaping, or cushioning.

Industrial Applications That Benefit from Low-Density Polyethylene

LDPE has wide applications where frequent handling or repeated movement takes place. Common uses include:

- Protective covers and liners

- Tanks and containers with low structural stress

- Chemical-resistant components

- Packaging, totes, and handling solutions

- Flexible tubing and low-pressure piping

- Food processing components

- Custom-formed trays or lightweight inserts

Its ability to remain flexible without cracking makes LDPE valuable for businesses that require durable components with repetitive use.

Choosing the Right Material for the Right Job

The two polyethylene sheet types offer strengths tailored to different conditions. The comparison below provides clarity:

HDPE Strengths

- Higher load-bearing capacity

- Increased resistance to abrasion

- Greater rigidity for structural components

- Ideal for outdoor or high-stress environments

- Strong chemical resistance for industrial fluids

LDPE Strengths

- Flexible and easy to form

- Lightweight and impact-resistant

- Performs well in repetitive motion situations

- Suitable for lightweight containers and liners

- Offers good resistance to chemicals and moisture

Temperature Resistance

Both materials maintain stable performance within a broad temperature range. HDPE is generally preferable for applications that face elevated temperatures or extended exposure to sunlight.

How Businesses Typically Evaluate HDPE and LDPE

Industrial decision-makers often compare HDPE and LDPE based on:

- Structural Requirements: Load, rigidity, pressure, and vibration

- Environmental Exposure: Chemicals, moisture, UV, heat, impact

- Fabrication Needs: Bending, welding, machining, forming

- Service Life Expectations: Long-term durability vs. short-term flexibility

- Cost: Balancing performance with budget

Since polyethylene materials come in many grades, sizes, and thicknesses, assessing these factors ensures reliable performance.

Why Selecting the Right Polyethylene Grade Matters

The wrong polyethylene grade can affect performance in several ways:

- Increased wear on moving components

- Cracking under load or impact

- Deformation in high-temperature areas

- Difficulty machining or fabricating

- Shorter service life and unplanned maintenance

Matching the correct material to industrial requirements, operations benefit from:

- Reduced downtime

- Improved equipment reliability

- Lower total cost of ownership

- Consistent performance throughout service life

This alignment is essential for businesses involved in material handling, packaging, manufacturing, processing, and fabrication.

How Johnston Industrial Plastics Limited Supports Polyethylene Selection

Johnston Industrial Plastics Limited carries a wide range of polyethylene sheets, rods, and custom-cut materials, supporting businesses across Canada with:

- Access to both low and high-density polyethylene sheets

- Material sizes suitable for machining, fabrication, and industrial upgrading

- Inventory availability for short lead times

- ISO-certified processes at key locations

- Support for multiple sectors, including mining, utilities, water treatment, and manufacturing

This combination of material choice, industry knowledge, and fabrication capability provides a clear path for selecting the most appropriate polyethylene grade. Businesses that rely on polyethylene components can benefit by partnering with a stable plastic manufacturing company. For industrial polyethylene solutions, Johnston Industrial Plastics Limited provides support with material selection and polyethylene supply.