At first glance, belt tension may not seem like a big deal. A belt that looks “tight enough” often gets ignored once it is installed. But behind that small adjustment lies a hidden danger that slowly eats away at machines. Too tight or too loose—both can quietly cause damage that only shows its true cost when it is already too late.

This article uncovers how incorrect belt tension affects your equipment, why the damage often goes unnoticed, and what simple signs can help you stop problems before they grow.

Why Belt Tension Matters More Than You Think

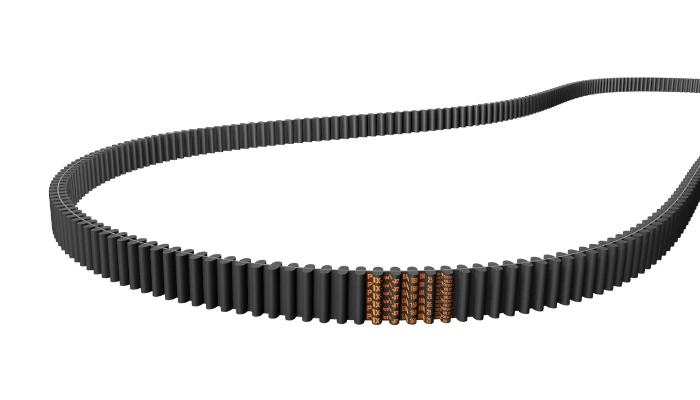

Belt tension controls how smoothly power moves from one part of a machine to another. When the balance is right, machines run quietly, smoothly, and with steady output. When the balance is off, trouble begins.

If tension is too loose, the belt slips. If it is too tight, stress builds up in parts that were never meant to handle that much pressure. Both situations slowly weaken your equipment.

Many failures that seem sudden are actually the result of long-term tension problems that were ignored.

Note:

If your systems rely on Correas industriales(Industrial Belts) , choosing the right tension support matters more than many realize. Pix Trans Spain offers helpful guidance for real-world belt challenges without complicated steps. If you suspect tension issues are affecting your equipment, Contact them and take the first step toward safer, smoother operation.

What Happens When a Belt Is Too Loose

Loose belts usually make their presence known through sound or performance issues. You may hear squealing noises, notice slower machine speed, or feel vibrations.

Here is how damage starts when a belt is too loose:

- The belt slips instead of gripping properly

- Heat builds up due to friction

- The belt surface wears down faster

- Energy is wasted during operation

- The machine struggles to deliver full power

At first, these issues feel minor. Over time, they lead to uneven wear, reduced machine life, and rising energy costs.

What Happens When a Belt Is Too Tight

This is the hidden danger many people overlook. A belt that feels “secure” may actually be pulling too hard on the machine.

When a belt is too tight:

- Bearings face heavy pressure

- Shafts bend under stress

- Motors work harder than needed

- Internal parts wear out faster

These problems do not show up right away. They slowly weaken the machine from inside. When a bearing finally breaks or a shaft bends, the repair cost suddenly feels huge.

Early Warning Signs You Should Never Ignore

Catching tension problems early can save time, money, and stress. Keep an eye out for these warning signs:

- Unusual noise during operation

- Vibration that was not there before

- Hot surfaces near belt areas

- Dust or rubber particles around the belt

- Reduced speed or poor output

When these signs appear, your machine is already asking for help.

How Incorrect Tension Shortens Equipment Life

Machines are built to work within certain limits. When belt tension crosses those limits, every moving part pays the price. The damage grows slowly, day after day.

Here is a simple comparison of what happens inside the machine:

| Belt Condition | Effect on Belt | Effect on Machine | Long-Term Result |

|---|---|---|---|

| Too Loose | Slips and heats up | Reduced power transfer | Faster belt wear |

| Proper | Smooth grip | Balanced movement | Long machine life |

| Too Tight | Over-stretched | High stress on parts | Early failure |

This balance is what keeps your equipment alive and reliable.

Why Many Tension Problems Go Unnoticed

One reason incorrect tension causes so much damage is that it does not always show obvious signs at first. Machines often keep running even while internal parts suffer.

There are three main reasons this happens:

- Operators focus on output, not internal stress

- Noise changes are slowly accepted as normal

- Regular checks are skipped due to busy schedules

This silent damage keeps growing until a sudden breakdown forces attention.

The Hidden Cost of Ignoring Belt Tension

Ignoring tension problems does not just affect belts or bearings. It spreads its impact across your entire operation.

Here is how the cost builds up over time:

| Problem Area | Short-Term Impact | Long-Term Impact |

|---|---|---|

| Energy Use | Higher power draw | Increased bills |

| Maintenance | Minor adjustments | Major repairs |

| Production | Small delays | Long shutdowns |

| Safety | Slight risk | Serious hazard |

What starts as a small adjustment issue can slowly turn into a business risk.

Simple Habits That Help Prevent Damage

You do not need advanced tools or complex checks to control belt tension. A few simple habits can make a big difference:

- Check belt tension during regular maintenance

- Listen for new sounds after belt installation

- Avoid over-tightening out of fear of slipping

- Replace worn belts before they affect other parts

Small steps taken early prevent large problems later.

The Quiet Enemy Inside Your Machine

Incorrect belt tension is a quiet enemy. It does not shout when it starts damaging your equipment. It whispers through small signs—extra noise, mild heat, or tiny changes in performance.

The real danger lies in how easy it is to ignore these whispers.

Machines warn us before they fail. The challenge is learning to listen before the warning turns into a breakdown.

Frequently Asked Questions

1. How often should belt tension be checked?

It is best to check belt tension during every planned maintenance cycle and after installing a new belt.

2. Can loose belts damage the motor?

Yes, continuous slipping can force the motor to work harder, slowly damaging it.

3. Is it safer to keep belts tighter than normal?

No. Over-tightening puts heavy stress on bearings and shafts and leads to early failure.

4. What is the earliest sign of wrong belt tension?

Unusual noise and vibration are often the first signs.

5. Can incorrect tension affect energy use?

Yes. Both loose and tight belts increase energy waste and raise operating costs.

Follow & Connect

Facebook: https://www.facebook.com/pixgermanygmbh/

Instagram: https://www.instagram.com/pixgermanygmbh/

Youtube: https://www.youtube.com/user/pixtrans

LinkedIn: https://www.linkedin.com/company/pixgermanygmbh/

Twitter (X): https://x.com/pixgermanygmbh

Google Maps: https://maps.app.goo.gl/Ls83bzangT1ipdQv5

For more infomatic content visit diginewsfeed.