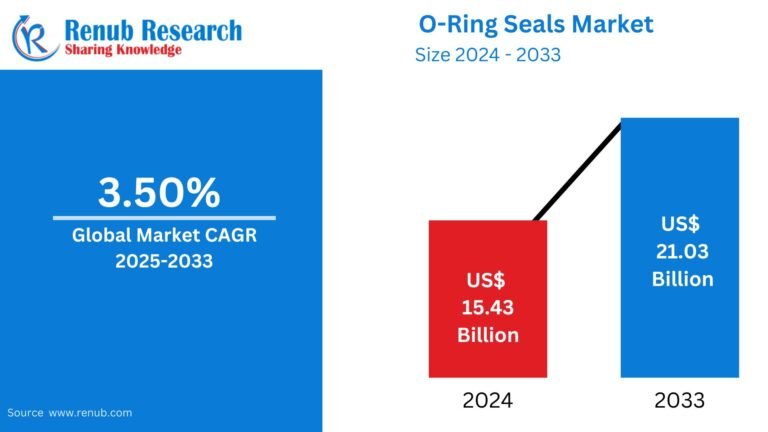

O-Ring Seals Market Size & Forecast 2025–2033

According to Renub Research Global O-Ring Seals Market was valued at USD 15.43 billion in 2024 and is projected to reach USD 21.03 billion by 2033, growing at a CAGR of 3.50% from 2025 to 2033. Growth is driven by expanding industrialization, increasing manufacturing activities, rising demand from the automotive and aerospace sectors, and the need for durable, cost-effective, and high-performance sealing solutions across critical applications. Advancements in elastomer materials, technological innovations, and growing adoption in high-temperature and high-pressure environments are further strengthening market expansion.

Global O-Ring Seals Industry Overview

O-ring seals are circular elastomeric rings designed to prevent leakage of gases or fluids between joined components. They are widely used due to their simple design, ease of installation, cost efficiency, and exceptional sealing reliability under both static and dynamic operating conditions. Common materials used include NBR, EPDM, Viton (FKM), silicone, and polyurethane, chosen based on requirements such as pressure resistance, chemical compatibility, and temperature endurance.

O-rings play a vital role in hydraulic systems, pumps, valves, engines, aerospace systems, oil and gas machinery, medical devices, and household appliances. Their ability to withstand harsh operational conditions, including exposure to aggressive chemicals, extreme temperatures, and high mechanical stress, makes them indispensable components across industries. Continuous advancements in material science have enabled the development of high-performance O-rings suitable for next-generation automotive systems, electrification applications, renewable energy equipment, and advanced manufacturing systems.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=o-ring-seals-market-company-analysis-p.php

Key Growth Drivers of the Global O-Ring Seals Market

Expanding Automotive and Aerospace Applications

The automotive sector is a major contributor to market growth, with O-rings extensively used in engines, transmissions, braking systems, air-conditioning systems, fuel systems, and electric vehicle components. The rise of electric and hybrid vehicles increases the need for thermally stable and chemically resistant sealing solutions.

Similarly, the aerospace industry demands highly reliable and lightweight seals capable of operating under extreme temperature variations and high pressure. Increasing aircraft production, fleet modernization, and emphasis on safety and efficiency continue to generate strong demand for premium-grade O-ring seals.

Industrialization and Growth in Manufacturing

Rapid industrialization across developing economies, expansion in machinery manufacturing, and heightened investments in oil & gas, power generation, mining, and heavy engineering sectors are creating robust market opportunities. O-rings help ensure system efficiency, reduce downtime, and minimize maintenance costs, making them essential for critical industrial operations.

Advancements in High-Performance Materials and Engineering

Material innovations such as advanced fluorocarbon elastomers, perfluoroelastomers, enhanced EPDM, and high-temperature silicone compounds are expanding O-ring application capabilities. These innovations enable seals to perform under severe thermal stress, corrosive media, and ultra-high pressure environments, improving equipment lifespan and operational safety.

Challenges in the Global O-Ring Seals Market

Raw Material Cost Fluctuations

Price volatility of raw materials such as rubber, polymers, and specialty elastomers may impact production costs. Manufacturers must balance cost efficiency with material performance and quality assurance to maintain competitiveness.

Performance Limitations in Extreme Environments

Although highly versatile, traditional O-rings may face limitations when exposed to extreme pressure cycles, abrasive particles, or ultra-high chemical aggression. This necessitates continuous material innovation, precision engineering, and improved sealing technology design.

Regional Insights into the O-Ring Seals Market

Asia-Pacific dominates the market due to strong industrial growth, large automotive manufacturing bases, and rapid infrastructure development in China, Japan, India, and Southeast Asia.

Europe remains a key market driven by advanced engineering industries, strong aerospace presence, and high-quality manufacturing standards.

North America witnesses stable demand owing to technological innovation, oil & gas industry activity, and adoption of performance-driven sealing solutions.

Middle East & Africa and Latin America are emerging markets supported by energy sector investments and increasing industrialization.

Competitive Landscape and Leading Companies

The O-ring seals market is highly competitive, featuring global engineering leaders and specialized sealing technology companies. Major participants include AB SKF, NOK Corporation, Zhongding Group, ElringKlinger AG, Freudenberg & Co. KG, Hutchinson (TotalEnergies), Parker Hannifin, Trelleborg Sealing Solutions, Saint-Gobain Performance Plastics, James Walker Group, Marco Rubber & Plastics, Greene Tweed, Bal Seal Engineering, Precision Polymer Engineering, and Horiaki India Pvt. Ltd. Companies focus on material innovation, customized sealing solutions, R&D investments, mergers and acquisitions, and sustainability initiatives to strengthen market positioning.

Product Innovations and Strategic Developments

Recent advancements highlight the introduction of next-generation EPDM sealing compounds for electric vehicle battery systems, integrated O-ring technology in precision valves, and expansion of high-performance polymer-based O-rings for demanding industries such as aerospace, energy, and semiconductor manufacturing. Strategic acquisitions and manufacturing expansions are enhancing supply chain capabilities and global reach.

Sustainability Initiatives in the O-Ring Seals Market

Sustainability is increasingly influencing sealing technology development. Companies such as Greene Tweed and Bal Seal Engineering emphasize environmentally responsible manufacturing, energy efficiency, waste reduction, extended product lifecycles, recyclable materials, and ethical sourcing practices. These initiatives not only reduce environmental impact but also support clients in achieving operational sustainability goals.

Market Segmentation of the Global O-Ring Seals Market

The market is segmented by material type, application, end-use industry, and region. Key material segments include NBR, EPDM, FKM, silicone, PTFE-based elastomers, and polyurethane. Major application sectors span automotive, aerospace, oil & gas, industrial machinery, medical devices, and household appliances. Geographically, the market is distributed across North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

Future Outlook of the Global O-Ring Seals Market 2025–2033

The Global O-Ring Seals Market is projected to witness steady long-term growth supported by industrial expansion, automotive innovation, ongoing infrastructure development, and advancing material science. Increasing adoption in electric mobility, renewable energy, precision engineering, and critical safety systems will continue to strengthen market relevance. As manufacturers emphasize high-performance sealing, sustainability, customization, and technological enhancement, O-ring seals will remain indispensable components across global engineering and industrial applications through 2033 and beyond.