Choosing the right window material is a long-term decision. Windows affect energy efficiency, maintenance costs, comfort, and even the resale value of a home. Among modern options, aluminum and fiberglass windows stand out as two durable, high-performance choices. While both offer clear advantages over traditional materials, they perform very differently in real-world conditions.

This article breaks down the key differences between aluminum and fiberglass windows so homeowners, builders, and designers can make informed decisions based on climate, budget, and performance needs.

Material Overview: What Sets Them Apart

Aluminum windows are made from lightweight metal alloys known for strength and slim profiles. They have been used for decades in residential and commercial buildings, especially in modern and high-rise construction.

Fiberglass windows are made from glass fibers embedded in resin. This composite material is engineered for stability and insulation, making it one of the most technically advanced window materials available today.

At a glance, aluminum emphasizes strength and design flexibility, while fiberglass focuses on thermal performance and durability.

Strength and Structural Performance

Aluminum is exceptionally strong for its weight. This allows manufacturers to create narrow frames with larger glass areas. For homeowners who want clean lines, wide views, or floor-to-ceiling windows, aluminum often delivers design options that other materials cannot.

Fiberglass is also very strong, in many cases stronger than vinyl, but it does not allow frames to be quite as thin as aluminum. However, fiberglass has a major structural advantage: it expands and contracts at nearly the same rate as glass. This reduces stress on seals and joints over time, improving long-term performance.

From a fastening and assembly standpoint, both materials rely on high-quality components to maintain integrity. Using corrosion-resistant fasteners is critical, and many installers source specialized hardware through suppliers such as fasteners – tokohasil to ensure consistent performance across climates.

Energy Efficiency and Thermal Performance

This is where the two materials differ most clearly.

Aluminum is a natural conductor of heat. Without thermal breaks, aluminum frames can transfer outdoor temperatures directly indoors, reducing energy efficiency. Modern aluminum windows often include thermal break technology, which significantly improves performance, but they still lag behind fiberglass in most climates.

Fiberglass is a poor conductor of heat, making it inherently energy efficient. It performs well in both hot and cold environments and helps maintain stable indoor temperatures. For homeowners focused on reducing energy bills or meeting strict building codes, fiberglass often has the advantage.

In regions with extreme temperatures, fiberglass windows generally provide better insulation and long-term comfort.

Durability and Weather Resistance

Both aluminum and fiberglass are durable, but they age differently.

Aluminum does not rot, warp, or crack, and it performs well in humid or coastal environments when properly finished. However, it can corrode over time if exposed to salt air and poor-quality coatings.

Fiberglass is highly resistant to moisture, UV exposure, and temperature fluctuations. It does not corrode or rust, and its dimensional stability means it retains its shape for decades. This makes it particularly suitable for harsh climates or areas with large seasonal temperature swings.

In both cases, proper installation, sealing, and the use of reliable fasteners play a major role in long-term durability.

Maintenance Requirements

Aluminum windows are relatively low maintenance. Occasional cleaning and inspection of seals are usually sufficient. Scratches or surface damage, however, can be more visible and harder to repair.

Fiberglass windows require even less maintenance. They can be painted, and the paint tends to last longer because fiberglass does not expand and contract significantly. Homeowners who want a “set it and forget it” solution often prefer fiberglass for this reason.

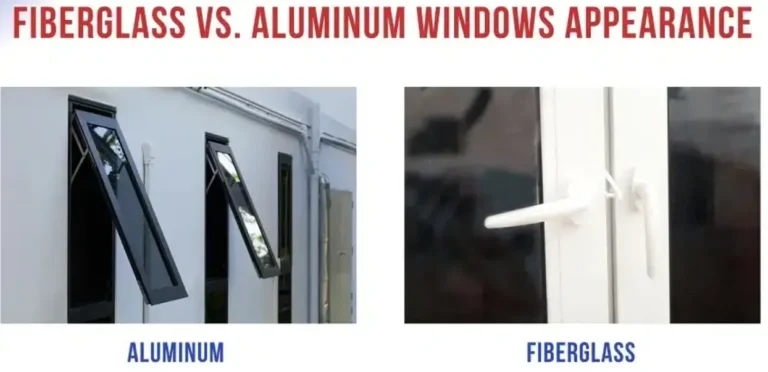

Design, Finish, and Aesthetics

Aluminum excels in modern and minimalist architecture. Its strength allows for sleek profiles, industrial finishes, and a contemporary look that works well in urban settings.

Fiberglass offers more flexibility in texture and finish. It can mimic the appearance of painted wood while offering superior performance. This makes it a good choice for both traditional and modern homes.

Both materials can be customized, but aluminum is typically favored for bold architectural statements, while fiberglass blends easily into a wider range of styles.

Cost Considerations

Aluminum windows are often more affordable upfront, especially for large openings or commercial-style designs. However, potential energy losses may increase long-term operating costs in some climates.

Fiberglass windows generally have a higher initial price, but they often deliver better value over time through energy savings, reduced maintenance, and longer service life.

The total cost should include not only the window unit, but also installation quality, hardware, and fastening systems sourced from dependable suppliers.

Which Is Right for You?

The best choice depends on priorities:

Choose aluminum if you value slim frames, modern aesthetics, and strong structural performance.

Choose fiberglass if energy efficiency, long-term durability, and low maintenance are your top concerns.

Both materials are premium options. When paired with proper installation practices and quality components such as professional-grade fasteners – tokohasil, either can deliver excellent performance for decades.

Understanding these differences allows homeowners to invest with confidence, selecting windows that truly match their environment, design goals, and long-term expectations.

Article about ” Aluminum vs. Fiberglass Windows: Key Differences Every Homeowner Should Know ” publish by: toko baut dan mur – tokohasil.com