When most people picture a crane in operation, they focus on the boom, the cables, or the massive hook assembly moving tons of material. But there’s one essential component that rarely gets attention despite playing a vital role in stability and safety—the headache ball.

This piece of equipment may look simple, yet it performs multiple critical functions that keep vertical lifting safe and predictable. The headache ball ensures that loads remain vertically aligned, helps control the position of the hook, and provides the necessary tension for smooth, balanced lifts. Ignoring its importance can lead to inefficient lifting, swinging loads, or even rigging failures.

What a Headache Ball Does

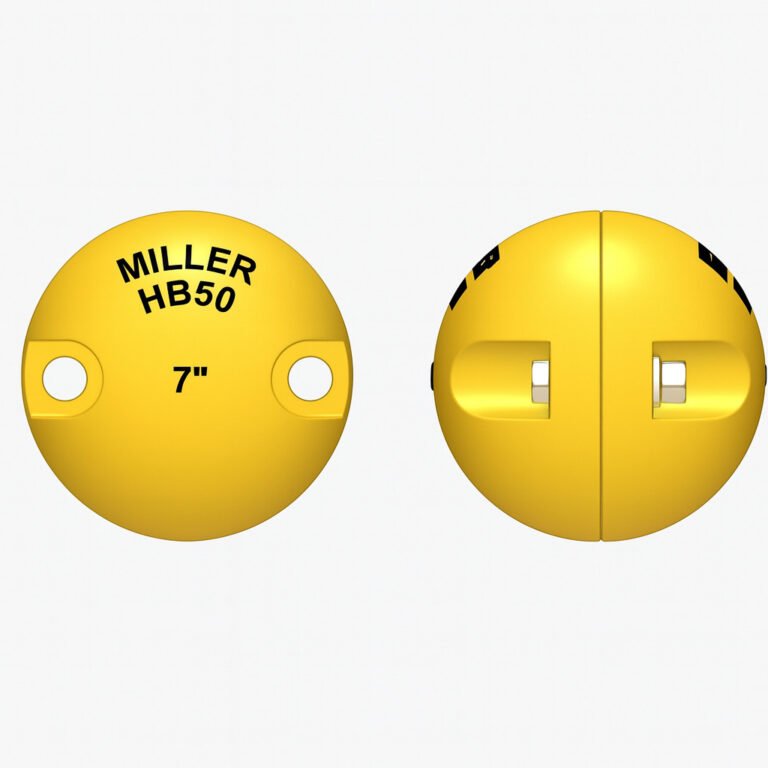

A headache ball—sometimes called a crane ball or overhaul ball—is a weighted spherical assembly attached to the crane’s hoist line just above the hook. Its primary purpose is to maintain proper tension on the wire rope and stabilize the line when the crane operates without a multiple-sheave block system.

The ball’s mass prevents the hoist line from twisting or whipping when unloaded, ensuring that the crane ball and hook stay aligned directly beneath the boom tip. This alignment improves operator control, particularly during single-line lifting operations where precision is vital.

In essence, the headache ball adds stability, reduces oscillation, and helps operators place loads accurately without line drift or spin. It is an indispensable tool for maintaining balance and consistency in day-to-day crane operations.

Weight and Alignment in Vertical Lifts

The weight of the headache ball is carefully calculated to counteract line movement and provide steady vertical tension. This balance is crucial for preventing the hoist cable from coiling or twisting—issues that can cause premature wear or sudden unspooling.

Heavier balls are typically used for larger cranes or longer hoist lines, where more weight is needed to maintain control. Lighter models suit smaller cranes or mobile units with shorter lines. The key is proportionality: the headache ball must be heavy enough to keep the line taut but not so heavy that it interferes with lifting capacity or line speed.

Proper alignment ensures the hook hangs directly beneath the boom, keeping the load steady during lifts, especially in windy or uneven conditions. Without this vertical stability, the operator risks side-loading the crane components, which can damage the hoist drum or cause load swing—a significant safety hazard.

Crane Ball Specs and Compatibility

Selecting the right headache ball depends on several factors: crane type, line diameter, working load limit (WLL), and operational environment.

Key Specifications to Consider:

- Weight range: Typically between 50 and 1,000 pounds, depending on crane size and lift type.

- Line diameter compatibility: The ball must fit securely to the hoist cable, maintaining a snug but movable connection.

- Attachment style: Options include swivel hooks, clevis hooks, and quick-latch assemblies. Swivel designs are preferred for minimizing line twist.

- Material and coating: Most are made from forged steel and finished with protective coatings to resist corrosion in outdoor or marine environments.

The proper headache ball crane setup must match manufacturer specifications to ensure safety compliance and consistent lifting performance. Using mismatched or uncertified components introduces unnecessary risk and may violate OSHA and ASME lifting standards.

Safety and Rigging Tips

Because the headache ball functions at the core of crane lifting control, it demands regular inspection and careful rigging practices.

Inspection Checklist:

- Examine the ball’s body for cracks, dents, or corrosion.

- Check the swivel or clevis connection for smooth rotation and signs of wear.

- Ensure the hook latch closes completely and moves freely.

- Verify weight markings and identification tags are legible and match documentation.

- Inspect the hoist cable for kinks or birdcaging near the connection point.

Rigging Best Practices:

- Always confirm that the ball’s Working Load Limit (WLL) exceeds the maximum load expected.

- Avoid over-lubricating the swivel mechanism—use only approved lubricants in moderate amounts.

- Keep your hands clear of pinch points when installing or adjusting the assembly.

- Store headache balls securely when not in use to prevent accidental rolling or impact damage.

Routine inspection before and after each shift is a key element of preventive maintenance. Operators should log findings to ensure traceability and compliance with safety protocols.

Real-World Job Use

Headache balls are used across diverse industries—construction, shipping, utilities, and heavy manufacturing—where cranes handle repetitive lifts with precision.

- Construction sites: Operators use headache balls on tower and mobile cranes to stabilize loads such as rebar bundles, formwork, or pipe sections.

- Ports and logistics: Dockside cranes depend on them to lower cargo hooks smoothly onto containers without swaying.

- Energy sector: Utility and maintenance crews use more petite headache balls for pole-mounted cranes and bucket trucks, ensuring safe equipment positioning in tight spaces.

- Industrial fabrication: Overhead cranes with single-line hoists are used to prevent twisting during assembly lifts and positioning of components.

In each case, the headache ball provides a crucial function: keeping tension steady and movement predictable. Without it, operators would face constant instability, requiring more corrections and longer cycle times.

Balanced Lifting Starts Here

The headache ball may seem like a simple accessory, but it performs an essential function in modern crane operations. By keeping the hoist line stable, aligned, and properly tensioned, you ensure every lift stays controlled from start to finish. Operators rely on its weight to prevent cable twisting, reduce oscillation, and maintain precision positioning under heavy loads.

Selecting the correct crane ball or overhaul assembly means understanding crane specifications, line compatibility, and environmental conditions. Regular inspection, maintenance, and safe rigging practices transform this often-overlooked piece of equipment into a cornerstone of lifting safety.

In the end, balanced lifting begins with balanced gear. Investing in high-quality headache ball crane components keeps operations compliant, efficient, and safe—no matter the scale of the project. For durable and certified crane ball and hook assemblies built to perform under pressure, contact Murphy Industrial Products, Inc.